WhatsApp)

WhatsApp)

Portland Cement Manufacturing ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, ...

why use vertical raw mill cement industry[crusher and mill] Cementing the Relationship Between DCS and PLC: A Review of ... control systems to offer vertical ...

Raw / Cement Mill, Cement/ Raw Mill – IndiaMART – Indian . This range of industrial machinery is manufactured using premium quality for Raw / Cement mills With ...

PENTA Engineering Corp. completed a cement plant raw mill and kiln conversion project at Hagerstown for Lafarlcim.

A cement mill (or finish mill in North American usage) ... These have been used for many years for the less exacting rawmilling process, ...

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

intensive process because raw materials, area where investment costs are high, Coal mill Dust filter Raw mill Rotary kiln Fig 1: Cement plant flow chart.

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT INDUSTRY. CEMBUREAU the European Cement Association, based in Brussels, is the representative organisation for .

A vertical raw mill is mainly used in cement plants for raw material grinding. Cement manufacturing components of a cement plant. Cement manufacturing process ...

Brief description of a cement mill. ... Raw materials; ... Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ...

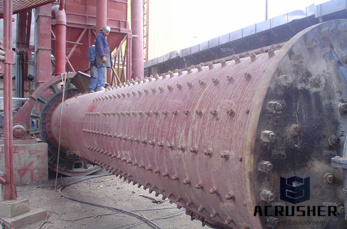

working principle. This cement mill is widely used in the grinding of cement raw meal, slag(GGBS plant), cement clinker, raw coal and other raw materials.

The raw mill considered in this study is located in a cement plant located in Sanliurfa, Turkey. The plant is a single chamber mill with mechanical circulation system ...

Cement Production: Raw Meal Production in Steps Perfectly mixed, accurately fed without pulsation, and precisely weighed. The key word is quality!

The raw material preparation stage of cement manufacture results in the production of a rawmix that is ... The nearly universal use of roller mills for raw milling ...

Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building ...

Raw Mix Preparation Raw Mix Optimization ... material proportions in the raw mill feed. As in ... • cement is ground to high quality from consistent clinker

Energyefficient grinding mill designed for a variety of cement types ... OK™ cement mill ... The modular design has parts commonality with OK raw mill, ...

The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of ... CEMENT RAW MATERIAL

In the cement industry, natural raw materials are processed to produce an end product which is a fine powder. As shown in the flow diagram, ... Raw material mill.

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. It''s mainly used in grinding raw materials and end products in ...

Loesche to deliver three VRMs to Sohag plant. ... a raw material mill with a capacity of 540tph of cement raw meal, a 350tph cement mill as well as a coal mill with ...

Laxmi Engineering Work :: Mini Cement Plant. Reducing the strain on the transport system, as most of the cement manufactured can be consumed in the nearby market.

Only grinding mill in the market designed as a cement grinder and not a modified raw mill ; Simple layout and fewer machines in the mill circuit . Send Enquiry;

WhatsApp)

WhatsApp)