WhatsApp)

WhatsApp)

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

Design features of rotary cement kilns ... Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding ...

Available in 50Lb bags, the Loucast 3000 castable refractory is designed to withstand high Sulphur fuel, erosion abrasion. Buy today from Sheffield Pottery!

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Nelson Machinery Equipment Ltd. Liquidations, Consignments, Appraisals since 1992

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

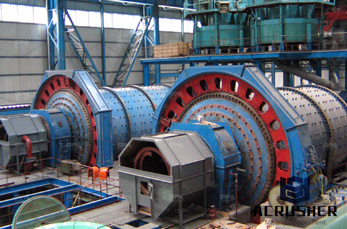

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the two ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

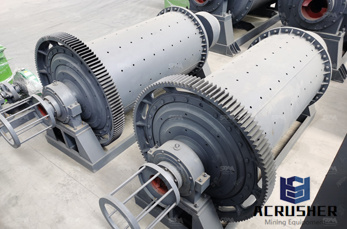

The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

FORGED STEEL BALLS — LARGE DIAMETER Forged Steel Balls are used for gold mining, cement factories, oil processing and large scale industrial applications.

2 HPGR High pressure grinding roll for the minerals industry Introduction During its relatively short history in minerals processing, HPGR technology

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Unused FL wet grind overflow ball mill, 27'' ( m) diameter x 46'' ( m) long. Discharge with MW (20,500 kW) gearless wrap around motor drive, 50 Hz ...

WhatsApp)

WhatsApp)