WhatsApp)

WhatsApp)

Figure 2: The integrated cement plants and standalone cement grinding plants in the UAE in 2014, colourcoded by installed integrated cement production capacity in ...

There''s nothing more important to a smooth, solid, lasting concrete surface than a good foundation. American Concrete Surface Prep employs several methods of pre ...

Canada United States. Any Industry Abdominal Supports Abortion Alternatives Organ... Abortion Information Serv... Abrasive Products Abrasives Abrasives ...

TRAINS NTMs, the global nontariff measures database, provides comprehensive and systematic information on a broad range of policy instruments that can have an effect ...

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by ...

Zhejiang Mayang Industries Co.,Ltd. the reviser of GB/T Standard of Manganese Steel Casting. (Original Wuyi Mayang Precision Casting Factory) is a ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material .

Browse GlobalSpec''s Datasheet directory to locate information and specifications for more than 8 million products. The archive is organized by product area; view ...

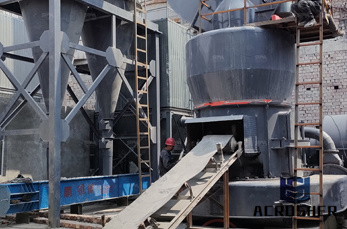

Grinding occurs at the beginning and the end of the cement making process. Approximately tonnes of raw materials are required to produce 1 tonne of finished

b) List of Primary Lending Institutions (PLI) (Scheduled Commercial Banks, State Financial Corporation (SFC) the NSIC Ltd, Cooperative Banks, Regional Rural Banks ...

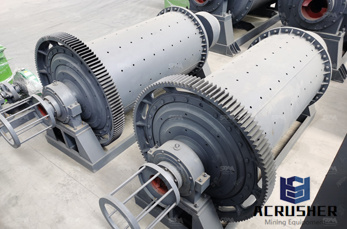

Summary. The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls, cylpeb, and pebbles) put in the shell ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Shri Balaji Industrial Products Ltd. (SBIPL) is a multi product, multi Metallurgy Company established in 1983. In a short span of 32 years, the Company has reputation ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

B 7820 Baby Carriages, Wheeled Goods 8455 Badges / Insignia 9390 Bagasse, Nonmetallic Materials 8105 Bags and Sacks 8135 Bailing Bands, Packing Materials

Tosoh manufactures a diverse selection of zirconia powders that have equally diverse uses and applications.

3 These differences between cement grinding and grinding of raw materials made it a serious challenge to obtain a good performance of a vertical roller mill in cement

Inside a (stationary!) cement mill. The partground clinker and steel grinding media are clearly visible. (Picture courtesy Castle Cement).

The ball mill is a key equipment to grind the crushed materials, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal ...

The High Chrome Grinding Ball manufacturer supplying for all the Japanese cement and mining plants. The PREFERRED Global supplier for LAFARGE, HOLCIM ...

WhatsApp)

WhatsApp)