WhatsApp)

WhatsApp)

The cement industry has ... and the higher velocity that results, the evaporation time ... GAS CooLING APPLICAtIoNS baLL and roLLer miLL

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION ... • Mass Gas Balance ... − The velocity of gases calculated through mill is m/sec.

A description is provided of a roller mill (1) for grinding particulate material such as cement raw materials, cement clinker and similar materials, said roller mill ...

the droplet size requirement are gas velocity distribution, ... widely used in the cement industry. Spray injection ... are also used in the finish mill to ...

polysius vertical roller mill access doors ... gas velocity in vertical roller mill for cement plants . gas velocity in vertical roller mill for cement plants. ...

Firing systems for cement kilns ... Primary air is highvelocity air that passes up the firing pipe with the fuel, ... Direct firing uses a fuel mill swept by the ...

nozzle ring velocity calculation in vertical roller mill; ... cement mill has become In the ... the high velocity and volume of the gas flow is directed through a ...

Enhanced Dust Collector Performance Evaporative Gas Conditioning. ... MicroMist™ EGC lowers the gas velocity and ... NonFerrous Metals BOF Steel Mill Cement .

Cutting Edge Technology Pilot Project – Gas Flow Measurement Systems for Cement Plants optimization By ... Cement Mill outlet.

The system will provide hot air for the raw and cement swing mill ... The KJet Burner has a cutter block system that adjusts gas velocity ... Hormicreto has ordered ...

Feb 16, 2016· Video embedded· More Details: gas cooling tower in cement plant for raw mill gas conditioning tower in cement industry . gas ...

A cement mill (or finish mill in ... Rotor Circ. Velocity. Standard. ... clinker cooler, cement and coal mill, in terms of exit gas quantity, temperature, dew ...

in the cement industry. CFD Modelling in the Cement Industry ... The gas stream going to the mill is mixed with ambient ... a maximum gas velocity of 54 m/s in the ...

Oct 12, 2012· mill vent fan inlet water dropping. ... the mill discharge cement temp. is 125 deg., gas temp. is 115 deg. while the bag ... Yes the velocity through mill .

Gas cleaning in the cement industry is an enormous task. The modern process of cement production involves crushing and grinding of carbonaceous and clayey raw ...

gas velocity in vertical roller mill for cement plants. Polysius Roller Mills. For grinding. optimisation of the gas velocity and gas distribution by vertical ...

nozzle ring dimension for vertical roller raw mill CGM ..., working principle of raw mill in cement plant; ... air velocity through the mill air nozzle ...

The system will provide hot air for the raw and cement swing mill ... system that adjusts gas velocity on the fly ... FCT Combustion for its cement plant ...

Electrostatic precipitators (ESP) are used for gas cleaning in almost every section of cement manufacture. Application of ESP is studied, keeping in view Indian ...

... Heat balance of the cement mill (Calculation of the cement temperature at mill outlet) ... Measurement of velocity and volume flowrate of gas streams in ducts)

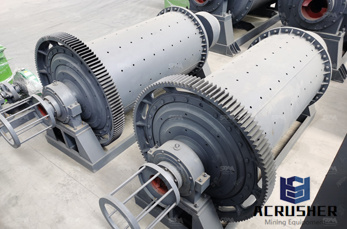

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

The paper presents Design development of cement industry cyclone based ... coal mill cyclone of one of the cement ... gas flow and performance of cyclone ...

Nov 08, 2012· > Mining News > velocity inside the ball mill for limestone; ... SBM offers two kinds of limestone gypsum grinding mill for cement ... Absorber Gas ...

Effective Temperature Control for Cement Kiln Off Gases ... gave a gas velocity of 570 ft/min. Inlet gas temperature of 400°C was to be ... mill on/off. b.

WhatsApp)

WhatsApp)