WhatsApp)

WhatsApp)

Raw material preparation. From the quarry to raw meal feeding into the preheater. ... provide the raw mill with the feed size range it requires.

from a captive operation by the cement plant. The portland cement manufacturing industry is relying ... (ESP) that follow the raw mill is returned to the process, ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Manufacturing process < All about Cement ... transport from outside the plant ... the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix ...

covered truck to cement plant where it is being stored in closed silos which is pneumatically conveyed to silos and directly to the cement mill ... 2 Raw Mill /Kiln ...

A 10 MW cement mill, ... These have been used for many years for the less exacting raw ... Cement milling is the largest user of electric power on a cement plant, ...

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

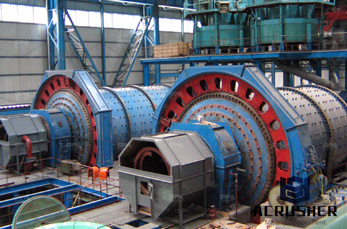

FL ball mill for cement grinding. ... requirements in terms of plant layout, mill drive, lining types and end product specifications, as required.

Modern Processing Techniques to minimize cost in Cement ... depends mainly on the hardness of raw materials and the type of mill used, ... in the cement plant.

... 1 3 13 21 65 83 109 Cement Plant Operation Handbook• v . 3 1 RAW MILLING ... 2 Cement Mill Specific ...

process of vertical raw mill in cement plant pdf. grinding process in raw mill. raw mill residue for cement,raw grinding machine residue for Cement Process and ...

PLANT OPERATIONS AND PRODUCTIVITY ENHANCEMENT A CASE ... Holtec has recently carried out Operational Audit in a cement plant having a kiln of ... Raw Mill .

The "work horse" of the cement grinding plant is the twocompartment ball mill,. LoescheMills for cement raw ... mill in cement industry pdf Cement raw ...

PROFESSIONAL CEMENT PLANT OPTIMIZATION, MODERNIZATION AND ENERGY CONSERVATION . ... Addition of a second raw mill or replacement of the existing raw mill.

Extraction of raw materials, ... • •Implementation of routine plant maintenance and good ... Capturing mill dust by fabric filters4 and recycling within the

cement mills can also be confi gured with a ... depending on available raw materials. SHELL INSIDE ... CEMENT MILLS MILL DESIGN Out cement grinding mills are also ...

be applied in cement grinding optimisation. Only the cement clinker grinding is discussed and area of raw material ... grinding plant is the twocompartment ball mill,

testing of a raw material mix proportion control for a cement plant raw mill. A systematic design method is given for raw mix

Advanced process control for the cement industry ... plant, optimizes the ... A raw mill stoppage is another

Ste. Genevieve Plant Tour ... The key operational areas of a cement plant are: • Raw material extraction ... • Raw mill fan 3,900 kW

This profile envisages the establishment of a MiniCement Plant with a capacity of 60,000 ... are transported by a belt conveyor and fed to raw grinding mill.

DETAILED ENERGY AUDIT AND CONSERVATION IN A CEMENT PLANT, ... Plant Raw Material Storage Raw Mill Hoppers Raw Mill Grinding Raw Meal Silos Preheater Tower

pdf vertical grinding mill for cement free manual,. ... Vertical roller mills are not only used for grinding cement raw materials but. Mill design ... cement plant ...

Energy and Exergy analysis of the Raw Mill in the Cement Plant 49 3 ENERGY AND EXERGY ANALYSIS OF THE RAW MILL IN THE CEMENT PLANT Introduction

WhatsApp)

WhatsApp)