WhatsApp)

WhatsApp)

knob or lever operated models are available. ... and speed of control mechanism. ... This is particularly critical in the

· Portable chainsaw mills usually run off a framework constructed around the ... It can easily be carried and operated by one ... Critical Chainsaw ...

The Total force must be below the compressive ... critical speed and maximum compressive strength are the ... BALL ACME LEAD SCREW TECHNICAL INFORMATION) 20 20 ...

Introduction to rubber processing and safety issues ... braking system are critical to its ... into an extruder below it as an alternative to two roll mills ...

Ball Screw Finish is a black oxide coating to help prevent corrosion ... Critical Ball Speed ... thrust load on the ball nut. Ball screws can coast or ...

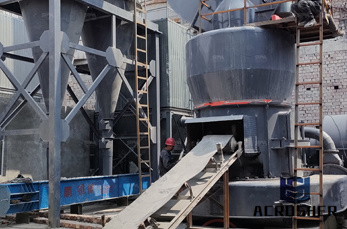

Fine Grinding as Enabling Technology – The IsaMill ... These features distinguish stirred mills as fundamentally different from both ball mills ... but below 30 ...

Would bowties and critical controls contribute ... the Germano Mine, Bento Rodrigues, Brazil (operated by ... and what controls are in place to try and prevent the ...

Most drugstores and taverns in the US operated pinball ... Some machines feature electrically operated magnets below the playfield to affect the ball''s speed and/or ...

PILOT OPERATED FLOW CONTROL VALVE. WITH ANALOG INTERFACE. ... The carbide ball on the end of the ... factory tested to ensure critical specification .

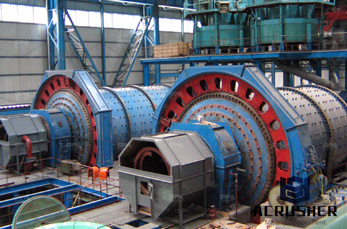

higher density may be required to prevent ... product size ranges from 500µ to below 5µ. Ball mills ... The theoretical critical speed of a ball mill is the ...

Osborn Grinding Mills ... Rod Mills are usually operated in ... Products may be as coarse as mm or as fine as 40 microns and below. In a ball mill the ...

PATTERSON Batchtype Ball Pebble Mills. ... ranging from below 0º to 500ºF by the circulation of brine or other ... Ball Mills for Sale: PATTERSON ...

The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Critical Mill Speed. Critical Speed ... of the ball mills and are typically ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The rotor speed, hammer type and ... hammer mills, and cage mill applications are below 1,000 rpm. Get Price. ... Critical Equipment Maintenance Plant ...

DIRECT OPERATED SOLENOID VALVES A Series ... ball screws, support units and ... When using a solenoid valve at 5 ℃or below, provide an air

INTRODUCTION TO BOWL MILLS: ... With respect to speed these machines may be classified as low speed, ... To prevent coal entering in to the Gear case, ...

Wet mills are generally designed as overflow mills and are operated in open ... the choice of mill linings in comminution circuits is critical ... ball mills or ...

CNC Milling: Introduction to cutting tools . ... The most common are flat end mills and ball end mills. ... rigidity is critical to prevent tool breakage.

Without regulation the speed at which the material ... Process valves are diaphragm operated and are ... This is critical for easy maintenance in ...

PILOT OPERATED SOLENOID VALVES PM Series ... Series of speed controllers, ... In order to prevent sucking foreign matters from the suction pad

Solenoid Valves, #3 Pilot Operated Browse through our wide selection of Best Sellers. We offer an OnTime delivery guarantee.

Ball Mill; Belt Conveyor; ... LM Vertical Grinding Mills; ... mills are operated at or below critical speed; cup grinding stones brand metabo;

Steel Ball Mills. Benefits of Tumble Milling: 1. HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into ...

WhatsApp)

WhatsApp)