WhatsApp)

WhatsApp)

Flexible gear grinding machines In recent years some extremely innovative gear grinding machines have come onto the market both in terms of how they are constructed and of how they operate. It is a wellknown fact that the two ...

External cylindrical plunge grinding Cylindricalangular infeed Cylindrical grinding longitudinal External cylindrical grinding is probably the most commonly used industrial grinding process. Rotationally symmetrical work pieces of ...

09/04 Grinding Meat page 2 Slide 3 Pretest Administer Pretest: Before we start the Grinding Meat training, I will give you a test before the training and the

1 The "SPIN GRINDING" Process and "BACK GRIND" Results There are three basic traverse systems in the field and "spin grind" testing of each of these grinding systems shows the reel will be "spun" ground with a "Back ...

1. Back Grinding 란? Wafer 뒷면의 불필요한 막을 제거하고 필요이상으로 두꺼운 뒷면을 깎아 내어 저항을 줄이고 열전도율을 향상시키는 공정. 2. Back Grinding 의 필요성 Sawing Operation 의 수월한 진행. Package Thickness의 ...

Backend processing refers to assembly and final testing. For use in the back grinding process to polish the backside of the wafer, ACCRETECHTOKYO SEIMITSU manufactures and sells polish grinders that combine globally ...

Basics of Grinding Fundamental Manufacturing Processes Video Series Study Guide 2 Another aspect of grinding wheels is their pore structure or density, which refers to the porosity between individual grains. This pore structure ...

Prior to grinding, wafers are commonly laminated with UVcurable backgrinding tape, which ensures against wafer surface damage during backgrinding and prevent wafer surface contamination caused by infiltration of grinding ...

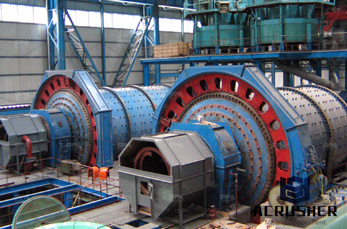

animation of grinding process ppt + ZCRUSHER Ppt of all crusher machines + Gulin Machinery jaw crushers animation ppt ore process crusher Coal crushing machine ... animated ppt on grinding machines + mtmcrusher Centerless ...

Grinding processes Workpiece Webb App Workpieces Go back You are here: KMT Precision Grinding AB / Workpieces Grinding processes / Grinding processes Grinding processes KMT offers a wide range of grinding processes

This is a back grinding tape best suited for thin wafer back grinding process. Capable of grinding wafers down to 50µm Reduces wafer warpage after grinding Heat resistance for mounting dicing die bonding tape "LE Tape" (up ...

How to Arc Weld (with Pictures) wikiHow Apr 26, 2016 · How to Arc Weld. Shielded Metal Arc welding is the process of joining two metal pieces using a flux covered electrode which is melted in an electric arc ... Get Price Online

15 UNIT 2 GRINDING Grinding Structure Introduction Objectives Types of Grinding Shapes and Size of a Grinding Wheel Straight Wheel Tappered Face Straight Wheels Cylindrical Wheel Ring 2 ...

Dicing Before Grinding (DBG) In contrast to most other techniques, the wafer is initially grooved and then ground in the DBG process. This technique offers outstanding advantages: the wafer can be ground to an ultrathin final ...

Because in DBG thinned wafers are never transported, waferlevel breakage is greatly reduced; and because die separation occurs during the grinding process, the backside chipping associated with thinwafer dicing is kept to a ...

Grinding Process Feed Solutions Gentle, NonMarking Polypropylene Brushlon EZClean, NonAbrasive Industry Standard Controls Proven reliable solutions for feeding parts from random bulk supply to Centerless, Double Disk Side ...

TAIKO Process Grinding Quality TAIKO Process Kiru, Kezuru, Migaku Topics Blade Dicing Laser Dicing Grinding Stress Relief DBG / SDBG Others Applications Example Applications Example DISCO Technical Review ...

Profitability has always mattered. What has changed in today''s globally competitive marketplace are the lengths you need to go to in order to ensure that every step of the machining process is as efficient and lean as possible.

PowerPointPräsentation Practical presentation: Process and feed back of field know how Process guarantee and Acid 4 Grinding Process with MK 95 and » Learn More PPT – GRINDING PROCESS CONTROL PowerPoint ...

Cement Process Chemistry Upload Share PowerPoint . Nov 27, 2009 · Cement Process Chemistry Presentation Transcript. About Cement . Cement Chemistry ; Cement ... cement processing plant, cement grinding machine ...

Modelling and Simulation in Manufacturing Technology „ Modeling and Simulation of Grinding processes" Prof. Dr.Ing. F. Klocke Structure ¾Introduction and motivation ¾The Grinding process important aspects for process modeling ...

Back Grinding 1. Back Grinding 란? Wafer 뒷면의 불필요한 막을 제거하고 필요이상으로 두꺼운 뒷면을 깎아 내어 저항을 줄이고 열전도율을 향상시키는 공정. 2. Back Grinding 의 필요성 Sawing Operation 의 수월한 진행.

TECHNICAL SOLUTIONS FOR GRINDING TECHNICAL GUIDE BEARINGS Bearings are mechanical devices used to reduce friction between two components that have a relative movement, most often rotational. Many shapes ...

Introduction of Product Introduction of Wafer Surface Grinding Machine Model GCG300 Junichi Y amazaki Meeting the market requirements for silicon wafers with high flatness and minimal damage, which have become increasingly ...

WhatsApp)

WhatsApp)