WhatsApp)

WhatsApp)

The NETZSCH Business Unit Grinding Dispersing, with headquarters in Selb, will acquire the company Ecutec Barcelona SL effective 17 November 2016.

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

provides alumina balls, alumina grinding ball, mill linings alumina brick inert alumina ball, China Origin.

Dry Milling and Grinding (Comminution) Equipment. Glen Mills distributes and maintains stock of equipment from some of the world''s best manufacturers of Dry ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

K Series Mobile Crushing Plant. Based on more than 30 years'' manufacture experience, millions of equipment units'' installation experience and abundant invested in ...

The DMQX bead mill from Union Process provides highly effective, reliable circulation grinding, producing uniform fine dispersions with superior product quality.

Figure 1. Diaphragm between the two compartments of the twocompartment mill – view from first compartment In the past 20 years, high pressure grinding roll (HPGR ...

85 0 102030 % loading in the mill 3 4 5 6 7 Loading factor K 1 Grate discharge Dry Grate discharge Wet Overflow discharge Wet Figure Effect of mill ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

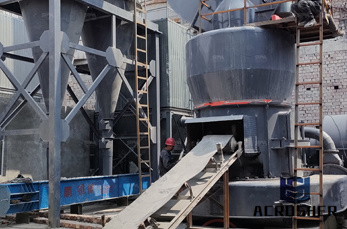

Crushing plant and grinding mill are widely used in the industry of mining, metallurgy, building materials, traffic, water conservancy and so on.

Now the mill steel ball on the market can be divided into two types according to the manufacturing process technology: Casting and forging. But the wear degrees are ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material.

PATTERSON 4''0" () dia. x 5''0" () long Jacketed Steel Ball Mill for Inks Manufacturing. PATTERSON® 6''0" () dia. x 6''0" () long Jacketed ...

Open the lid to your Ball Mill and add the following: 150 grams of Potassium Nitrate, 30 grams of Charcoal Powder, and 20 grams of Sulfur ( if your lead balls are not ...

Fitzpatrick''s lab grinding mill for size reduction offers superior accuracy scalability. Discover how our equipment can help minimize product losses!

Improving The Efficiency Of Fine Grinding – Developments In Ceramic Media Technology Curry D C1; Clermont B2 1Technical Superintendent Mineral Processing; .

Unused FL wet grind overflow ball mill, 27'' ( m) diameter x 46'' ( m) long. Discharge with MW (20,500 kW) gearless wrap around motor drive, 50 Hz ...

WhatsApp)

WhatsApp)